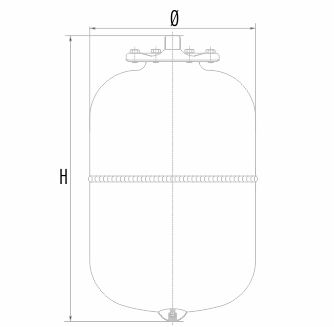

EXPANSION VESSELS WITH REPLACEABLE MEMBRANE FOR CLOSED HEATING SYSTEMS

MODEL |

HEIGHT |

DIAMETER |

MAXIMUM WORKING PRESSURE |

STANDARD PRECHARGE PRESSURE |

CONNECTION |

|---|---|---|---|---|---|

VR5 |

300 |

160 |

8 |

1.5 |

¾ ” |

VR8 |

316 |

200 |

8 |

1.5 |

¾” |

VR12 |

295 |

280 |

8 |

1.5 |

¾ ” |

VR18 |

430 |

280 |

8 |

1.5 |

¾” |

VR24 |

483 |

280 |

8 |

1.5 |

¾ ” |

VR35 |

440 |

365 |

8 |

1.5 |

¾ ” |

VR50 |

585 |

365 |

8 |

1.5 |

¾” |

Working temperature -10°C – 100°C | Rubber membrane: EPDM

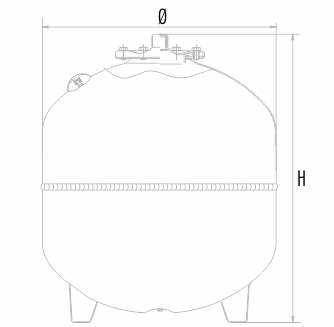

EXPANSION VESSELS WITH REPLACEABLE MEMBRANE FOR CLOSED HEATING SYSTEMS

MODEL |

HEIGHT |

DIAMETER |

MAXIMUM WORKING PRESSURE |

STANDARD PRECHARGE PRESSURE |

CONNECTION |

|---|---|---|---|---|---|

(mm) |

(mm) |

(bar) |

(bar) |

(inches) |

|

VRV35 |

450 |

365 |

8 |

1.5 |

¾ ” |

VRV50 |

582 |

365 |

8 |

1.5 |

¾ ” |

VRV60 |

668 |

365 |

8 |

1.5 |

¾ ” |

VRV80 |

717 |

415 |

8 |

1.5 |

1” |

VRV100 |

675 |

495 |

8 |

1.5 |

1” |

VRV150 |

790 |

550 |

8 |

1.5 |

1” |

Working temperature -10°C – 100°C | Rubber membrane: EPDM

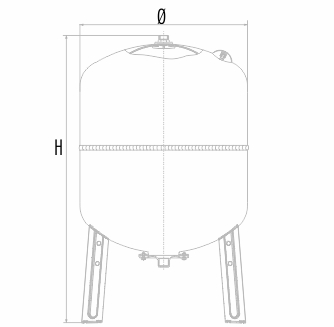

EXPANSION VESSELS WITH REPLACEABLE MEMBRANE FOR CLOSED HEATING SYSTEMS

MODEL |

HEIGHT |

DIAMETER |

MAXIMUM WORKING PRESSURE |

STANDARD PRECHARGE PRESSURE |

CONNECTION |

|---|---|---|---|---|---|

(mm) |

(mm) |

(bar) |

(bar) |

(inches) |

|

VRV200 |

1085 |

600 |

8 |

1.5 |

1” |

VRV250 |

1051 |

650 |

8 |

1.5 |

1 ” |

VRV300 |

1212 |

650 |

8 |

1.5 |

1” |

VRV400 |

1198 |

750 |

8 |

1.5 |

1 ¼ ” |

VRV500 |

1438 |

750 |

8 |

1.5 |

1 ¼ ” |

VRV600 |

1634 |

750 |

8 |

1.5 |

1 ¼ ” |

Working temperature -10°C – 100°C | Rubber membrane: EPDM

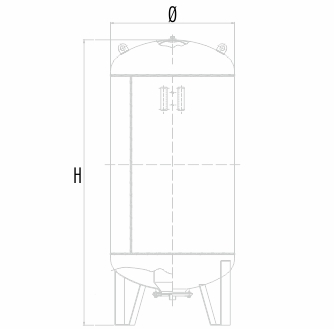

EXPANSION VESSELS WITH REPLACEABLE MEMBRANE FOR CLOSED HEATING SYSTEMS

MODEL |

HEIGHT |

DIAMETER |

MAXIMUM WORKING PRESSURE |

STANDARD PRECHARGE PRESSURE |

CONNECTION |

|---|---|---|---|---|---|

(mm) |

(mm) |

(bar) |

(bar) |

(inches) |

|

VRV200 |

1085 |

600 |

8 |

1.5 |

1” |

VRV250 |

1051 |

650 |

8 |

1.5 |

1 ” |

VRV300 |

1212 |

650 |

8 |

1.5 |

1” |

VRV400 |

1198 |

750 |

8 |

1.5 |

1 ¼ ” |

VRV500 |

1438 |

750 |

8 |

1.5 |

1 ¼ ” |

VRV600 |

1634 |

750 |

8 |

1.5 |

1 ¼ ” |

Working temperature -10°C – 100°C | Rubber membrane: EPDM

Processes & Services

Our Branches

Client Testimonials

Here’s just a few of our clients reviews and testimonials